Paver Package

Note, our packages bundle most components of the Wet & Dry Processes for a finished product.

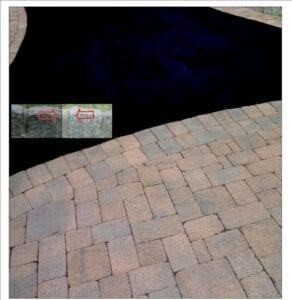

Paver Restoration With

Polymeric Stabilized Sand

(hardens like a rock)

Available in Graphite or Beige

We use only the finest longest-lasting Polymeric Products by Alliance

With a Haze-Free Guarantee!!

OUR PAVER PACKAGE LEAVES NO STONE UNTURNED

FLAT SURFACE CLEANING MACHINE

PAVER TAMPING TO SECURE ALL RESETS IN PLACE

PAVER PACKAGE

DRIVEWAYS - POOL SURROUNDS - WALKS

7 STEPS

- Apply Oxygenated Sodium Hypochlorite Antifungal To Kill Mold Mildew Algae To Clean & Brighten

- Power Wash Aggressively & Restore Original Color - Include Belgian Block Detailing at no extra charge (if applicable)

- Remove Moss, Weeds & Old Stone Dust or Sand

- Apply Vegetation Killer Between The Stones To Ensure A Weed-Free Environment

- Reset Stones As Needed

- Install Polymeric Sand* or Stone Dust

- Seal with Matte or Wet (Gloss) finish (Optional)

*Available in Beige or Graphite Gray (see right)

Which is better & how not to get ripped off?

Stone dust is ground stone, course as sand, but a heavier aggregate than play sand. It primarily is used to reestablish the stability of wobbly stones, as well as enhance aesthetic value. It doesn't prevent weeds from coming through and is easily disturbed by a leaf blower or heavy downpours. It is the least costly and usually comes in a gray color.

Polymer sand basically serves the same purpose as stone dust and is as coarse as sand. The main difference is that polymer sand hardens, is more like grout, and helps prevent weeds from coming through and isn't disturbed by a leaf blower. It sometimes is offered in colors when available. It is more costly than stone dust and will last longer providing better long-term results.

This is a subjective question. Unless you want an enhanced "wet" look, we believe that it is inexpensive enough to simply power wash and return the pavers to its original color—less the natural weathered effect every few years by simply removing all of the bio-pollutants and reapplying polymer sand or stone dust than it is to seal and enhance the color. Many believe it also makes the pavers somewhat more slippery, which is not a great idea for pool surrounds, driveways, or walks. Besides that, we haven't found a seal to be resistant to the snowplow blade or shovel and even in the end, sealed pavers still get dirty and have to be power washed!

So, unless you are looking for a wet or shiny and slippery finish, save your money!

Here's the scoop. Ever heard of McDonalds? They're known for using "fillers."

Given that the polymer sand is upwards of $20+ for a 50 lb bag and the depth of the paver if cleaned deep and thoroughly is about 2.75” deep, what many contractors do is fill the gap after washing with about 2.5” of regular white play sand, which sells for around $3.50 for 50 lbs.

To be clear, the shortcut method, percentage wise makes the cost of materials 90% less expensive by using the polymer "dusting" method.

Cheap is always expensive. Be aware.

Cheap prices most often mean that the job you'll be paying for is nothing more than a surface “polymeric dusting” consisting of 1/4".

This is the biggest biggest farce and rip-off as far as we are concerned.

When next year rolls around, this method without any vegetation killer is sure to allow moisture to seep through the thin membrane of polymer sand during the winter months thereby causing frost upheaval and/or allow weeds to break through for certain.

The polymeric sand manufacturer clearly states on their packaging that the polymeric sand should be packed as deep as possible in between each block to assure long-lasting results.

In some instances, the installer may not have provided sufficient separation between the paver to allow for deep cleaning or enough polymeric sand to fall in between the joint. Other issues i.e., using the wrong base when laying the pavers can also cause failure and may be the reason to believe that product failure may be inevitable sooner than expected.

This is why we believe it's critical that a deep cleaning is provided in an effort to harvest all the debris out from between the blocks during the cleaning process, and vegetation killer applied to assist in making certain the joints will not be pierced by weeds, leveling any of the divots or raised blocks so the snowplow doesn't catch any of the corners of the edge of the block and tear it out.

No paver should be sitting higher than another by greater than 1/8" before applying the polymeric sand since the snowplow drivers handling paver driveways can adjust their plow to 3/16" or 1/4" while still removing your snow.

Our method avoids all the shortcuts and will ensure longer-lasting results have to do your pavers less frequently or only when they get so dirty that you simply can't stand it any longer.

Please contact us anytime for a no-obligation evaluation.

Please contact us any time should you have a question or wish to receive a no-obligation evaluation. We look forward to hearing from you.